Introduction

Our experiences have led us to successively make three versions of our bikes.

For me, Cécile, the story began when a German cyclist made me try the recumbent bike he had made. I liked it a lot, but it took me a long time to afford such a bike, more expensive than an upright bike.

In 2016, after months of research, comparisons, and a few tests of all the recumbent bikes I can find, my choice stops on a StreetMachine Gte from HP Velotechnik that I buy second-hand.

Why this choice? Because this bike, suspended from the front and back, is very comfortable, efficient, stable, maneuverable, sturdy and high enough to make me feel safe in traffic.

I really enjoyed it on a muscle bike, but the desire to go further, faster and the pleasure of tinkering with it led me to think about adding a motor and a solar panel for autonomy.

In 2018, I will glean information from the Sun Trip in Lyon. These adventurers make me dream when they leave for China. I thank Michel Olchewsky again for having been kind enough to present me in detail his own bike, very successful.

First episode: our solar bikes in 2019 = 1 panel 100 Wc

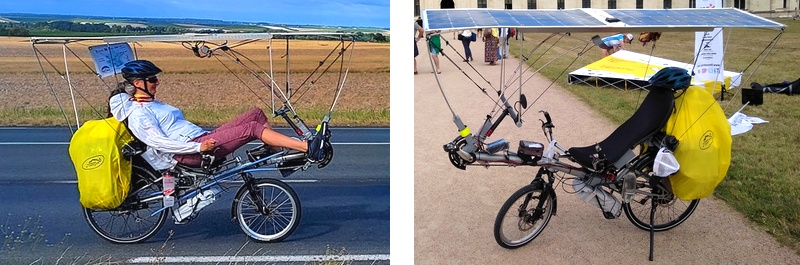

Cécile's bike – 2019

StreetMachine Gte bike (HP Velotechnik), Xofo 350W rear wheel reduced motor, 48V 10.5Ah battery (capacity: 500 Wh), basic Chinese controller 48V 20A, 1 single panel SunPower 100Wcrête (4×8 cells, about 1 € / Watt), 1 Chinese solar controller CTKEV300.

As I don't have much strength, I wanted to build a light bike, able to withstand the falls that will inevitably occur and transportable by car or train, so removable quickly. In addition, my bike must be able to easily pass in the elevator of our building!!! It's also a challenge!

Thus the engine is the lightest in its class.

Similarly, the load-bearing structure of the solar panels, easy to disassemble, with a reduced footprint, will carry a panel of 4×8 cells, or 0.50 x 1 m. I make it with fiberglass tent stakes, add a guy wire system so that it offers flexibility and stability. I end up with the result of a slightly curved panel. This is a bad idea: the efficiency of solar capture is much worse than when the panel is flat, allowing each cell to receive the same light intensity.

Feedback Cécile – 2019

In use, the bike is very pleasant: I climb some passes to Mont Cenis and I attend the arrival of the Sun Trip in Lyon in 2019. This bike is very manoeuvrable while remaining compact, its structure is very stable and robust to shocks, it is light, with a total weight of about 25kg.

Nevertheless, I realize that it is not motorized enough for the mountains: the 100 Wp panel and the 500 Wh battery, perfect on sunny summer days, are a bit fair when the weather is poor.

Victor's bike – 2019

Straight bike, 250W rear wheel reduced motor, 36V 11Ah battery (400 Wh capacity), basic Chinese controller 36V 20A, 1 Chinese CTKEV300 solar controller + trailer with solar panel. Victor's right bike pulls a 16-inch single-wheel trailer and modifies its hitch (system with wooden gimbal) to anchor it to the luggage rack.

Victor Feedback – 2019

Victor comes to the conclusion that such a hitch deprives him of taking the train and that the trailer is not stable and robust enough for an autonomous journey of several days. In addition, his posture on the bike generates significant pain on the buttocks and ants in the wrists over the kilometers. Finally, the shadow cast by the cyclist on the trailer significantly thwarts the capture of the sun.

This experience led him to Cyclociel in Villeurbanne where he tried different types of machines, and in particular trikes that he discarded for several reasons: a ground clearance too low that puts the face at the level of the axles of the truck wheels, the need to physically compensate for the cant of the road, the 3 wheel tracks on the road that capture much more irregularities of terrain, Impossible access to some bike paths. Victor then also chooses a recumbent bike, and in particular the StreetMachine Gte from HP Velotechnik. Choice never denied, we still appreciate it today, at each of our outings for its comfortable position, excluding any pain in particular thanks to a handlebar offering a low position of the arms.

We will observe later that the rear wheel of the trikes supports very important forces in the corners which generates many breaks of spokes. This will reinforce our choice of 2 wheels.

Episode 2: our solar bikes for the Sun Trip France 2020 = 2 panels of 100 Wp

We decided to double the surface of solar panels to benefit from a greater solar potential and gain autonomy: 2 SunPower 100W peak panels.

Cécile's bike – 2020

StreetMachine Gte bike, same 350W rear wheel reduced motor, same basic Chinese controller 48V 20A, new 48V 21Ah (1000 Wh) battery, 1 Chinese CTKEV300 solar controller.

New challenges: Despite a double length of the previous one, the structure must remain easily removable, compact when disassembled, light flexible and must not hinder the vision when I ride.

I realize this structure with stakes for tent hoops, aluminum for more lightness. The fulcrum at the front of the bike is on the boom, by a wooden structure fixed by two hose clamps and by another carbon structure, T-shaped fixed by collars used in model making on helicopters.

The assembly is energized by stays of adjustable length. Stability is non-negotiable. A structure that oscillates or whose oscillations are too slowly dampened, can cause falls or deviations on the road, thus endangering the cyclist. In addition, significant shear forces on a structure lead to its failure, sooner or later. The panel is fixed using screws and 6 butterfly nuts along each length.So I can quickly dismantle my structure and carry it in a light backpack that I have made, and that I carry in my saddlebags.

By unscrewing only one side of my panels I can orient it using a wedge that I come to place between the reinforcements and the panel.

Feedback Cécile – 2020

In use, unscrewing my 6 butterfly nuts every night tires me and I finally prefer to direct my bike directly by choosing a suitable support point. A steerable structure should be quick and easy to maneuver.

The carbon T of the supporting structure of the panels splits under the effect of the swelling of a small piece of wood (because of moisture) that fits into it and supports the aluminum hoops. An improvised ligature made of plastic collars will solve the failure.

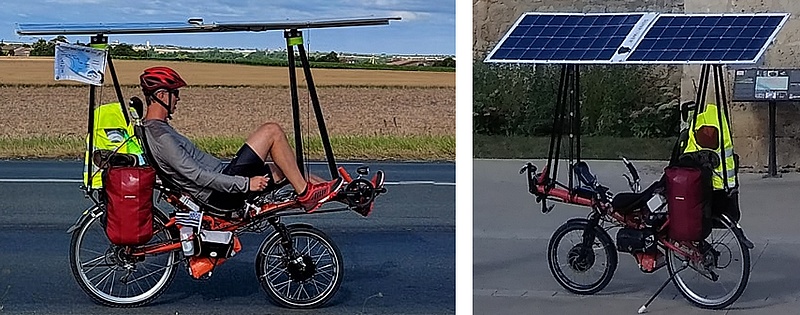

Victor's bike 2020

StreetMachine Gte bike, Xofo 500W front wheel reduced motor, same basic Chinese controller 48V 20A, new 48V 21Ah battery (capacity 1000Wh), 1 Chinese CTKEV300 solar controller.

Victor prefers a 20-inch front wheel motor because he wants to keep the 3-speed Dual Drive system integrated into the rear wheel hub (26 inches).

The installation of the panels on the load-bearing structure is very easy. The search for lightness and robustness led him to discard Bosch profiles, which were too heavy for his taste. It will retain aluminum U-shaped profiles (purchased in DIY stores). It will take 4 per post to ensure right-left and front-rear rigidity and allow redundancy in case of accidental deterioration. In addition, the total size of the machine, including its adjustable and removable panels, must allow the bike to enter the elevator of our building!

The panels are fixed on a horizontal wooden "beam", itself plugged into door hinges. The uprights are fixed on the boom using two homemade, wooden jaws. Their ability to turn around the boom limits the risk of breakage in the event of a shock or fall of the bike. A system of rope stays, light and strong, stiffens the whole while offering a certain flexibility.

Victor Feedback – 2020

For 5 weeks, the 2 bikes crisscross without major problem the 3200km of the Sun Trip France 2020. Here are our observations:

- In use, the reduced engine will demonstrate its performance on climbs, with a corollary tendency to skid when grip is reduced (gravel for example) especially when the bike is loaded.

- The load-bearing structure of the panels is tested during a fall in the Rhone Valley, without damage. In any case, its repairability is ensured very easily: in case of breakage of a U-profile, it is possible to arm it with a piece of wood and tie it with adhesive and / or string. Spare parts are easily found in many countries.

- The kickstand of the bike gives way and will be repaired with a steel tube.

- The bikes nevertheless reveal their limit in the solar recharge of the batteries: the 2 bikes move slower than the other machines and impose longer pedaling days. This trip will define the ideal surface of solar panels: 0.8m wide by 2.10m long.

- In addition, the strong heat wave of summer 2020 requires, for the future, to provide sun protection on the lower legs and arms via longer and wider panels.

- Victor experiments with the orientation of the panels by hand while driving but notes that the wind can also rotate them, with the risks that this represents. The conclusion he draws is that orientation must be made possible when stationary, but not during taxiing where additional strings must lock the panel in a horizontal position to avoid any catch in the wind.

My desire to do the Sun Trip Alpes 2022 triggers the preparation of version 3 of our bikes …

Episode 3: our solar bikes for the Sun Trip Alpes 2022 = 2 motors

The climbs planned for this adventure require to significantly strengthen the motorization of the 2 bikes.

Features common to the 2 bikes:

- 2 independent motors, each with its own controller and screen,

- new 300Wp panel of 6×15 cells in 1 single panel,

- bicycle battery kept 48V 21Ah (1000 Wh),

- 1 Chinese CTKEV300 solar controller.

Cécile's bike – 2022

Choice: 2 reduced motors front and rear wheel 500W each, 1 rear wheel trigger, front motor cut-off on front brake handle, rear engine cut-off on rear brake handle. 1 temperature sensor on one of the 2 motors. No Statorade (coolant).

For this version of bike I abandon the structure in flexible hoops for my panel. I agree with Victor's choice of an easily adjustable and repairable structure.On the other hand, I choose to build a structure that leaves me a clear view, without uprights in the field of vision, making a "triangular window".

Why not install a single 1000W motor? Why not choose a pedal motor?Why not choose a direct drive motor with regeneration?

Yannick Aspe and Béa Cazanave had alerted us to the problem of simple motorization. In addition to the fact that redundancy on the motors makes it possible to feel safe in the event of failure of one of the motors, it is necessary to consider the best efficiency of a dual motorization.Indeed to provide the same power the total current consumed will, a priori, be the same on a double motorization of 500W or on a simple motorization of 1000W. In reality, the fact of distributing this total current into 2 flows to feed the 2 motors, allows them to heat much less and to operate with a better efficiency. A single motor, crossed by a stronger current, would heat up uphill, when the current draw is intense.

A pedal motor seemed to me to be an excellent choice, but I did not retain it so as not to add weight on my boom which is already undergoing significant efforts at pedaling, it seems to me. (Even if it's just me pedaling!)

Questioning the usefulness of regeneration

The subject of regeneration is difficult to decide.Admittedly, we are often on the lookout for the slightest electrical charge to store in our batteries, and not regenerating downhill represents a loss of energy that makes regret.On the other hand, experience shows that in good weather, the panel provides sufficient energy. Thus the regeneration then becomes problematic and imposes a management of the charge of the battery: when it is fully or almost charged at the top of a neck, it is necessary to be able to dissipate the energy provided by the regeneration on the descent, so as not to damage the battery.On the other hand, benefiting from the braking of the direct drive engine is a real comfort.

Finally, considering the extra weight of direct drive motors and their torque a little less good than that of reduced motors, I decide not to choose this type of motor. For my small muscles, the weight of a wheel is a concern when I have to disassemble and manipulate it, or manipulate the bike. It is a choice that can eventually be questioned.

Victor's bike 2022

Double motorization: 500W front wheel reduced motor + new Tongsheng TSDZ2 48V 750W pedal motor

Attached to the 3-speed Dual Drive hub on the rear wheel, Victor has no choice but a pedal motor. He chooses the TSDZ2 with torque sensor, the installation at the end of the boom is easily achieved by tinkering with an aluminum collar to prevent the motor from swivelling. He prefers the Tongsheng to the Bafang BBS02, yet more powerful but heavier, important point when installed at the end of the boom. In use, the motor with torque sensor imposes a more sustained pedaling which can generate more fatigue at the end of the day, so do not hesitate to increase the level of assistance a little. It installed the trigger for starting and avoiding skidding of the front wheel. This engine is also very efficient for driving in the energy saving in case of bad weather, on the first position.

For the structure, 4 additional strings at each front and rear corner immobilize the panel while rolling while allowing orientation at a standstill. The set is lowered by 15cm to reduce the wind grip, sometimes problematic.

2022 feedback: dual motorization

The maximum engine temperature recorded during this Sun Trip in the Alps was 80°C. This means that our dual motorization is proving its worth: the efficiency is very good because little energy is lost in the form of heat.

Feedback: solar charging with the CTKEV-300 controller

On this 2022 version of our bikes, a problem arises: the open-circuit voltage of the panel (Vco ~60V) exceeds the full charge voltage of the battery (54.6V). The CTKEV300 Boost regulator is based on the fact that the Vco panel voltage must be lower than the battery voltage to cut the charge. But this is not our case so at the end of charging, the charger lets the current pass from the panel to the battery and the battery continues to charge. In our case, above 54.6V the BMS of the battery goes safe and opens the charging circuit. Phew, we are protected (because we plugged the charger into the battery charging socket). But there is no question of using the safety of the BMS in normal operation, and we make the decision to build a cut-off circuit at the end of the charge using an Arduino nano 3.3 BLE and a bi-stable relay (no current consumption) positioned in series between the output of the charger and the battery.

The algorithm opens the relay when the battery voltage reaches 54.6V, and closes the relay when the battery voltage drops below 54.0V.

Attention, to avoid any electric arc on the relay during its closure, the algorithm also checks that the panel voltage (output of the charger) is greater than 40V before closing the relay.

There is still an advantage to having a panel with high voltage, rather than two panels in parallel: the boost of the charger does not have too much work to raise the voltage Vmpp of the panel (here about 45V) to the battery voltage (54.6V), which avoids voltage losses. On the other hand the panel current is half as high as with two panels in parallel: the charger does not heat up at all in our case.

The Arduino also allows us, using two current sensors (ACS758) to measure the current on the panel side (charging) and motors (discharge), as well as the panel and battery voltages. We can therefore deduce the powers, daily energies, etc …

Connected to the phone by Bluetooth BLE, we are developing an Android application that will allow us to record all this data, as well as geolocation thanks to the phone's GPS.

We can share the electrical diagram and Arduino and Android software on request.

Conclusions

Our bikes are accomplished and have proven to be perfectly adapted to the Sun Trip Alpes 2022 rich in mountain climbs. During this adventure, energy consumption and production were balanced, we never recharged to the sector. The speed of traffic observed on the flat was close to 30km / h, between 15 and 20km / h in the climbs of the passes, which seems prudent to us to circulate without forming an obstacle too irritating for motorists and without taking too great risks in case of fall. (fortunately, we never checked this point)

We are not considering any major changes, but I am thinking about installing a front deflector to gain frontal and lateral aerodynamics. We became aware of the importance of tires and racking, which is something to watch out for to go far.

In general, the maintenance and monitoring of mechanics is an important point.

Another important point is to make sure to protect the electronics from moisture by covering all delicate elements with plastic at night to avoid dew or rain.

One more small thing: Our measuring devices, chargers, converters, cables… are held by elastic collars that allow them to move when hit, more or less strongly. No rigid fasteners to prevent breakage. The elastics are easy to disassemble and reinstall if necessary. So much time and energy preserved!

Still, our bikes are powerful, comfortable, maneuverable, fast and offer an attractive autonomy. So many qualities to the extent of our desires for small roads, sumptuous landscapes, without any constraints.

Annexes

Upcoming topic – Come back soon!!!