It consists of a set of Li-Ion elements (called “cells”) associated in series and in parallel, to which is added an electronic protection system, the BMS. Its role is to prevent too deep charging or discharging and to balance the tensions between the Li-Ion elements.

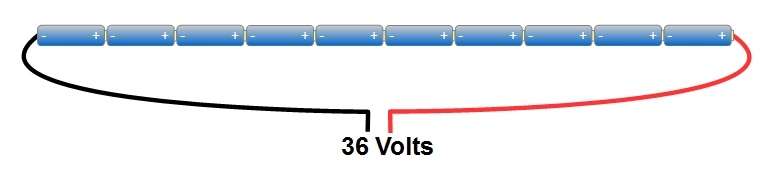

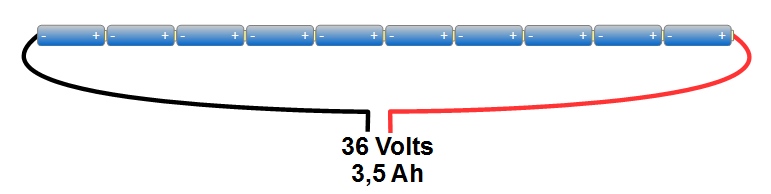

Bicycle batteries consist of cells either of “18650” format in reference to their dimension (diameter = 18mm, length = 65mm), or of “21700” format (diameter = 21mm, length = 70mm, from the automotive world). The cells have a nominal voltage between 3.6 Volts and 3.7 Volts. Pairing cells in series, based on battery voltage rating To make a nominal 36-volt battery, 10 cells are seriated.  To manufacture a nominal 48-volt battery, 13 cells are put in series. For a nominal 52 Volt battery, 14 cells. Parallel cell pairing, based on battery capacity Manufacturers offer cells in different capacities: – for cells of “18650” format, the proposed capacities are 2000, 2500, 2900, up to 3500 mAh (milliAmpere-hour). – for cells of “21700” format, the capacities offered are 4000 and 5000 mAh. In the example shown below, 3500 mAh cells were chosen, the highest capacity available to date. If the battery has 1 series, its overall capacity is 3500 mAh or 3.5 Ah.

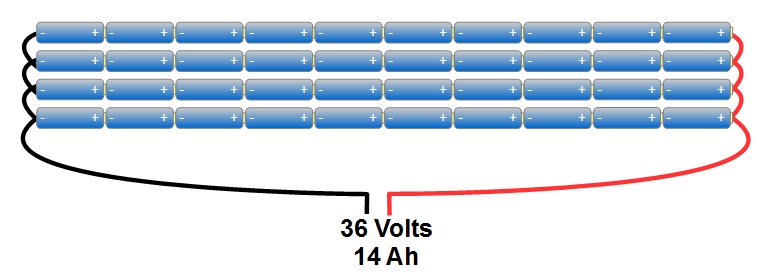

To manufacture a nominal 48-volt battery, 13 cells are put in series. For a nominal 52 Volt battery, 14 cells. Parallel cell pairing, based on battery capacity Manufacturers offer cells in different capacities: – for cells of “18650” format, the proposed capacities are 2000, 2500, 2900, up to 3500 mAh (milliAmpere-hour). – for cells of “21700” format, the capacities offered are 4000 and 5000 mAh. In the example shown below, 3500 mAh cells were chosen, the highest capacity available to date. If the battery has 1 series, its overall capacity is 3500 mAh or 3.5 Ah.  In the second example shown below, still with cells of 3500 mAh, 4 series of 10 cells were associated in parallel. The resulting battery has an overall capacity of 14 Ah.

In the second example shown below, still with cells of 3500 mAh, 4 series of 10 cells were associated in parallel. The resulting battery has an overall capacity of 14 Ah.  High capacity cells (3500 mAh) have the advantage is to be able to store more energy at equal weight. That is, at the same capacity, the battery will be lighter, which is an advantage for the solar cyclist. But these high-capacity cells are often more expensive. It is important to choose good quality cells. Indeed, there are lower quality cells on the market that sometimes do not meet the advertised capacity, or whose longevity will be shorter, when it is not a question of safety. It is reasonable to check if the cells of a battery come from major manufacturers whose quality is recognized as Samsung, LG, Sony or Panasonic / Sanyo …

High capacity cells (3500 mAh) have the advantage is to be able to store more energy at equal weight. That is, at the same capacity, the battery will be lighter, which is an advantage for the solar cyclist. But these high-capacity cells are often more expensive. It is important to choose good quality cells. Indeed, there are lower quality cells on the market that sometimes do not meet the advertised capacity, or whose longevity will be shorter, when it is not a question of safety. It is reasonable to check if the cells of a battery come from major manufacturers whose quality is recognized as Samsung, LG, Sony or Panasonic / Sanyo …