Introduction

These bikes are used daily for family logistics. Compared with a 2-seater trailer, the cargo bike provides safety, easy interaction with children and greater carrying capacity (100kg load). Because they are used to travelling by bike, they are a natural choice for long-distance journeys. However, because of the heavy weight, the difference in altitude has a major impact on range in the non-solar electric version.

Following an initial electric realisation based on Cycle Analyst, these are my first solar realisations. These bikes have each covered only 2500km in solar (but respectively 9,000km / 3years and 22,000km / 7 years in total). The solar/non-solar conversion takes just one hour.

The time investment is between 200 and 300 hours in total – mainly due to development errors generating several versions. The financial investment is around 6,000 Eur per solar bike – to be put into perspective by their use as a replacement for a car for the last 7 years.

Detailed technical overview

The framework

Twelve V2 Frameworks for the following reasons:

- The neutral position, neither too sporty (Bullit type) or too raised (Bakfiets type)

- Steering by cables which provides real flexibility in handling even if less robust and sensitive to cable tension settings

- The possibility of separating the front and rear frames, improving the transportability and the evolution of the frame (possibility of lengthening or shortening the bike by changing the front frame), even if finally little used in 7 years.

- The really successful design and the general technical achievement of the bike

- The many attachment points to change the front structure according to use

- The acceptability of 2.4 inch tires

While picking up the second frame from Douze Cycles, I met Arno Liégeon who prepared Eric Morel’s bike for the 2018 Suntrip. He gave me lots of assembly tips, such as the uniball + silent block for the solar surface / bike connection for example.

The only point that I regret is the impossibility of mounting a suspension fork (equipment available on other models which do not lend themselves so easily to solar DIY) due to the geometry not intended for this adaptation.

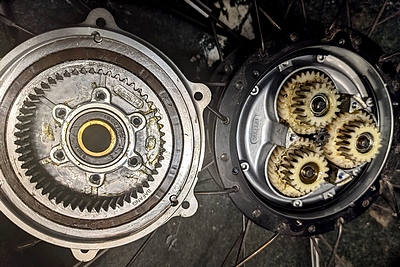

The engine

Two motors

- Direct Drive Nine Continent RH212 wheel motor (on blue frame bike)

- Equivalent Chinese model motor in 26-inch rear (on white frame bike)

- Bafang G311 Std reduced wheel motor in 20 inch front (two frames).

With a total mass of 170 kg, a direct drive motor allowing regeneration is essential: low max. 15% on a hilly stage for us, but above all greatly increased safety and increased brake pad life – factor 3 in city use. And in a descent at 20% encountered in the depths of the Corrèze, the brakes alone would not have held.

However, a 26” Direct Drive motor requires power for this type of load that leads to rapid overheating on hills, so the addition of a reduced motor on a 20-inch wheel at the front (3kg or 2% of overweight under load). On the advice of Justin (Grintech), the Direct Drive remains permanently powered with a temperature limit and the reduced motor only comes as a support to help in the acceleration or hill phases.

Regulation: common setpoint of the Cycle Analyst on both controllers, with an offset of around one volt in the ramp start threshold for the front motor controller: as soon as the power demand corresponds to a stabilized speed on a flat road, only the Direct Drive motor remains active and the front motor causes no energy loss due to its freewheel.

Due to the assembly error above, one of the front motors had to be deactivated in the middle of the journey and the advantage of the dual motorization was obvious.

The Battery

Specifications: guaranteed autonomy of 100km/day regardless of the weather (target of 5 hours per day and 5 days in a row max. to respect the well-being of children, passive in cargo ). Considering the load, riding without assistance is not possible (following a controller fault on the second day, 5km on a false flat descending without headwind was very difficult for me).

2 batteries per bike of the following type (purchased in France):

- 48V assembled 13S7P i.e. 17.5Ah or 816Wh (about 1.6kWh theoretical, much less in practice due to load settings, see next chapter).

- Samsung INR18650-35E cells (Li-Ni-Co-AlOx), Li-ion reference at the date of purchase, 2C in discharge, i.e. 3.3kW theoretically possible. 0.5C in load corresponds to approximately 800W, therefore recovery + non-critical synchronous solar production.

- Standard Hailong box and standard BMS, including a Bluetooth with cell monitoring, absolutely recommended!

- Parallel mounting by Anderson Powerwerx PD-8 distributor, expensive but solid therefore making connections easy and safe (see wiring diagram).

Voltage settings (conservative empirical values, to be optimized):

- Mains load set at 52.5V (theoretical at 54.6V) => Significant loss of capacity to avoid stressing the cells and allow solar charging and recovery.

- Cyclist analyst low power reduction threshold at 43V: thanks to the large capacity of the two batteries, the “reserve function” allows to have a little margin before complete cut

- Controller cut-off set to 41V (theoretical cell destruction 39V) => as before, to optimize the life of the cells and to keep the BMS cutoff in redundancy

- Solar MPPT load set to 53V: value to allow some recovery. Surely not sufficient value for mountain stages – To be measured.

- Regeneration voltage set at 53.5V : value with empirical safety factor to keep the BMS shutdown in redundancy

At 12Wh/km for 22.5 km/h on average, possibility of a full day in the rain without being stopped. Over 20 days of travel, only a mains recharge was necessary following two very rainy days with strong headwinds.

Connecting batteries in parallel, even if technically simple, can cause problems:

- if a BMS stops, transfer of the entire charge/discharge to a single battery, without feedback.

- if a BMS stops (overheating for example), and restarts automatically => Uncontrolled voltage balancing of batteries generating very large currents.

- => 25A fuses prevent the worst, but the cells can be subjected to overloads without it being visible.

Solar equipment

Photovoltaic panels and mechanical support

Panel specifications:

Monocrystalline silicon type cells with panel efficiency >20%

Width of about 80cm, width of a mountain bike handlebar to which I am accustomed

Support specifications:

1-axis orientation system, mechanical or electrical, automatic regulation if possible (see study by Yannick Aspe).

Sizing of the support to avoid any excessive bending / vibration in both axes because monocrystalline c-Si cells are slightly flexible on a single axis (the semi-flexible panels are intended to be glued to more or less flat surfaces such as a yacht or motorhome)

Encapsulation of the cells on a light but not very protective plastic support: need to size the support so that it protrudes a few millimeters from the solar surface.

Cooling: Power loss rate of –0.30%/°C (Sunpower C60 cells), therefore point fixing rather than over the entire surface.

At the time of making this bike, I contacted the applied research institute for solar systems Fraunhofer ISE – where I currently work – to possibly ask them to make panels that met my expectations. Despite their negative response, through them I was able to contact Phaesun, a solar equipment distributor who provided me with the Suntriper reference modules: Sunpower SPR-EFlex 170Wp / 3kg / 1153 x 810 x 20 mm / 6×8 back contact cells – allowing by their specific architecture a better adaptability to micro-cracks, inevitable in our application. MC4 connectors replaced by Anderson.

Scratch between panel and s 20x20x 1.5 mm aluminum supports and 3M reflective red tape.

Module / aluminum frame fixing by scratch (or Velcro) self-adhesive: vibration isolation + easy disassembly/reassembly (for transport or storage)

Following 10 days by the sea, the sand deposited noticeably alters the effectiveness of the panels

Solar Regulators

C-Tec 300W, one per panel: easy to set up, quite responsive – at least for the price. Only standby consumption seems significant to me – to be measured.

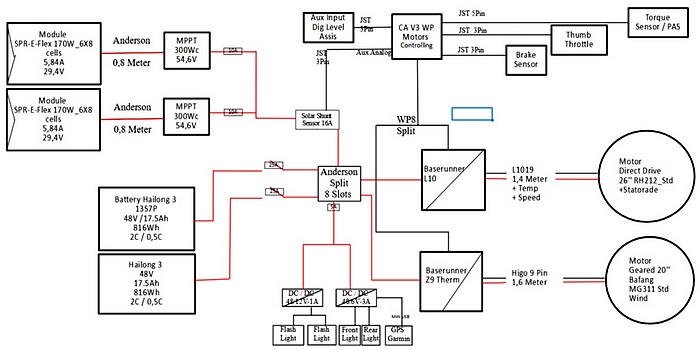

Cabling

Anderson 30A connectors for power (reliable, simple and robust, manual cable production without special pliers with soldering of the lugs), JST for information (not convinced by the design but standard at Grin and I don’t know of any no others, 2/3/4/5 piece sets available and inexpensive).

One-line wiring diagram

Legend: red: power – section from 1mm² to 3mm² / black: information – approximately 0.2mm²)

Cycle control:

A single Cycle Analyst for all the regulation: configuration requiring a certain investment of time but very formative. Grin’s after-sales support is impeccable. Beware of customs fees when ordering directly.

Supporting structure: 4 versions over 2 years

Version 1.0: June 2020

- AW-6060 T6 aluminum structure – only alloy / heat treatment available from the local aluminum dealer: light, rigid, easily drilled, but very difficult to bend (requires T6 tempering – see following Versions).

- Orientation by a set of strings and bungee cord tensioner: an unrefined solution but ultimately effective and reliable.

Benefits:

- Easy to assemble structure: 3 tubes for the substructure, uniball silent block and aluminum panel support.

- Firm hold of the panel: even on degraded surfaces and despite the absence of a suspension fork, no sagging

- Driving feeling similar to the non-solar version

Disadvantages:

- 170Wp insufficient for long stages, predictable from the famous empirical value of 4 wh/wp/day.

- Manual steering while driving complicated or even dangerous on a two-wheeled vehicle (impromptu visit to a ditch following a semi-trailer overtaking with a steeply inclined panel) More difficult steering on degraded road surfaces because of obstructed view.

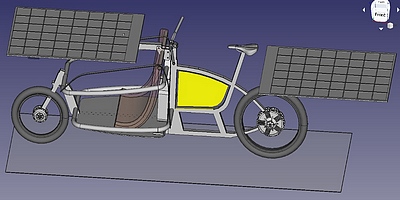

Version 1.1: June 2021 Prologue Suntrip (4 days by bike)

Figure 11: 3D visualization for clutter/interference validation

- Addition of a second panel on the trailer: “All-Terrain – Mule” model, a local brand that offered me this equipment as sponsorship. Fixed mounting of a panel on an aluminum structure with uniball/silentblock to orient the panel when stationary and access luggage. A single-wheel trailer allowing a very natural driving but the size of the panel can be a problem during narrow passages such as bike path studs.

- Orientation by stepper motor on the front structure: based on a GX24R370, 12V 10RPM and pre-wired PWM regulation. simple electrical installation (plug-n-play) but more complex mechanical integration.

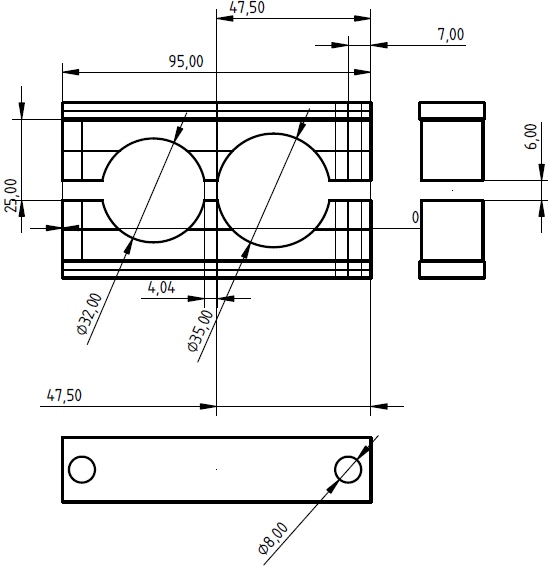

- Finalization of the aluminum structure/cordura fabric to accommodate the children: the most complex part of the project at the mechanical level because bending of tubes in diam.35x ep. 2mm at 90° on 6060-T6 alloy requiring metallurgical know-how that I do not have.

Benefits:

- Sufficient solar power for long stages,

- Easy orientation: DC motor solution with practical and functional manual regulation. However, given the crosswind sensitivity of a leaning panel, automatic regulation is not ideal for bi-porters (developed and then discontinued by Douze Cycles).

Disadvantages:

- Very long hitch making narrow passages very difficult because the trajectory for passing the front panel is not necessarily the same as for the trailer with the rear panel.

- Sign edges sometimes considered aggressive for reverse/pedestrian traffic on cycle paths

- Reverberation of the panel on the face: in the case of using a panel with a smooth front face, a glare sometimes appears.

- Shadow cast by the cyclist on the panels: difficult to quantify but in this configuration generates shading in the morning and at the end of the afternoon, which necessarily requires separate charge regulators / MPPTs.

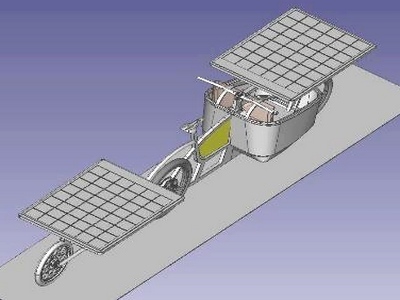

Version 2.0: July 2021

First test with the roof panels: height still too high (still 15cm of margin above the helmet when driving) and central anti-oscillation stay too vertical (initially installed to support the deformation of the tube under the modules).< /p>

Following the test of Peter’s Bullit freighter and Sybille’s bike during the 2021 prologue, the reluctance regarding the roof panels has been lifted. This version was developed in 4 weeks before departure with the whole family.

Benefits:

- Optimal irradiation without shading, assuming that the cleanliness of the modules (dead leaves for example) is regularly checked.

- Unique orientation for the entire solar surface: here with 4 reusable rilsans collars: the forces of resistance to the air while driving are minimal when the panels are horizontal

- Cycling protection against UV rays and bad weather: impossible to go back once tried: No more sunstroke, very acceptable temperature even in heat waves

- Offset of the panels well above the obstacles encountered on a cycle path: with 70 cm wide at barrier height, even anti-scooter chicanes are no longer a problem.

Disadvantages:

- Frame forces at important attachments:

20mm beech base and 20x5mm aluminum reinforcements

Frame / solar structure connecting flanges: 20mm beech base and 20x5mm aluminum reinforcements

- Tubes in the field of vision: quick and unobtrusive acclimatization

- Impossible orientation while riding: mandatory horizontal position because compared to recumbent bikes or trikes, the seated position requires a greater height which leads to a significant torque as soon as transverse forces (side wind) are applied. 2m² of solar surface with an angle of inclination greater than 15/20° is enough to destabilize a two-carrier freighter.

- Significant longitudinal oscillation – of the order of a centimeter – when passing over asperities which “stop” the bike but not the solar structure: not enough “triangles” in the structure seen in profile, flattening parallelogram effect. The reinforcements/stays in tubes of approximately 10×1.5mm (D.xEp.) do not buckle and effectively cancel this oscillation.

- Production of curved tubes on 2 axes: given the know-how acquired on the more complex production of the child protection structure, I took the opportunity to apply this technique allowing me to solve in a tube the constraints size and angle.

- Significant risk of breaking solar cells when the bike tips over. The aluminum support protruding from the panels avoided visible deformation of the panels but the cells must have suffered – electroluminescence test not yet carried out.

- Weight of the total structure: difficult to estimate because weight of screws and bolts unknown. Total with panels surely above 15kg.

- Height of 2.05m can be a problem in tunnels (such as in Besançon along the canal under the mountain)

Version 2.1: July 2021 -> Current

Bicycle configurations during our trip. Children have 3 independent Velcro protections that can be combined according to the weather: anti-insect net, transparent plastic for rain, opaque Cordura for shade.

Version used during our trip. Since Jenny’s bike has a higher mount on the front bend tube and she needs less height, only a pair of braces are needed. In my case, I had to add reinforcements to the front in the middle of the route to better manage the oscillations.

Cycle parts and miscellaneous:

- Both frames are equipped with telescopic seatposts (not suspended). Equipment now standard in mountain biking which allows you to adjust the saddle height over the entire travel while riding, and thus

- to easily swap bikes without tools and without marking the seat post (28cm size difference for us),

- temporarily lowering the saddle for more safety on tricky passages or at traffic lights, giving better resistance to tipping under heavy loads,

- to adjust the saddle a little lower so as not to damage a little more chic pants (city use).

- Mavic EX729 rims / 26 inches / 36 holes / 29mm wide / double eyelet / reinforced welding, intended for downhill mountain biking. Combined with Schwalbe 26 by 2.35 (60-559), downhill inner tube, inflated to 2.5 Bar. Despite the loaded weight, no problems to report. This combination provides a balance between comfort, rolling resistance and satisfactory cornering. To go further, I recommend reading this page (source: https://www.schwalbe.com/fr/rollwiderstand)

- Shimano SLX 11-speed groupset 11-46 cassette – unfortunately the 46-tooth sprocket does not seem compatible with the idler wheel of the Douze frame. Chainrings 28 and 42 teeth, without derailleur (adapter necessary because frame not provided for this configuration): change to 28 by hand, in the case of long climbs.

- Microshift Advent 9-speed 11-42 cassette group: derailleur/cassette/shifter kit currently available at 120 Eur all-inclusive, Shimano compatible, reliable and pleasant even if the cassette staging is quite wide. 9 Speed chain in my opinion much more robust than those for 11 and 12V.

- Ergotec H-Bar Space, an affordable copy of Peter’s Jones H-Bar which convinced me – the difference compared to straight MTB handlebars is noticeable – combined with Ergon grips slightly extended from the handlebars to compensate its lack of breadth. Having a slightly higher position and being able to change the position of the hands solved the onset of shoulder pain for me.

- Flat peg pedals (I only ride automatic on mountain bikes), still allowing you to “pedal around” while having a unique pair of multi-activity shoes,

- SQlab 610 saddle for Jenny, the revelation for her after several models tested over the years.

- “Shigura” hydraulic brakes, the forbidden combination according to the manufacturers but so effective of Shimano levers and Magura MT4 calipers – 4 pistons, coupled with Shimano 203 mm discs.

- Roxim X4 front light, for their quality of manufacture, their powerful but very uniform beam – 180 degree visibility, allowing night trips (technical condition to enjoy sunsets on the beach outside of a racing frame Suntrip).Combined with 12V orange flashing LEDs on advice from Christophe du Suntrip permanently on the back.

- Garmin Dakota GPS guidance: 10 years old – therefore very inexpensive, indestructible, waterproof, very readable because LCD screen (the more sun, the better the contrast), powered by the battery on converter DC/DC micro USB 5V, free OpenStreetMap maps on https://extract.bbbike.org/?lang=fr, route loaded in GPX from the also free cycle.travel site, offering perfect routes for cycle tourism, and planner of a route over several days to optimize the daily km/altitude ratio. Use of the site on Smartphone also possible, with connection to the GPS by OnTheGo USB adapter (generation of GPX by OSMand with offline maps in the case of weak network).

- Rearview mirror: to comply with the Suntrip participation rules, even if I found this equipment previously useless, but ultimately very pleasant to use. Functional and robust Busch + Müller model, now used daily to monitor children on the way to school.

Feedback

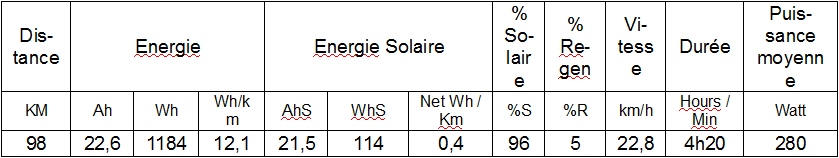

- Daily average values:

Cycle Analyst values were taken every evening, allowing a comparison between the two bikes (only average values appear here).

Comments:

- 100km and 4h30 per day: compromise between correct daily progress and the well-being of children.

- consumption of 12Wh/km for an average of 23 km/h: high value due to laden weight and permanent assistance to minimize journey time while maintaining the correct intensity of effort. Aerodynamics not optimized.

- 96% share of solar energy: satisfactory value given the sometimes capricious weather

- 5% regeneration: low value but linked to the relatively flat course (avoiding mountain ranges as much as possible) and to a perfectible setting.

Highlights

Versions 1.1 and 1.2 were used successively on Suntrip prologues but only for 2 days each time. Version 2.0 only a few tens of kilometers. We did about 2000 km with version 2.1.

Once the problems listed in the following paragraph have been resolved, their use takes family cycling travel into another dimension: without assistance, 20 to 30 km per day are possible, and around 60 km with assistance for both parents. In comparison, we achieved an average of 100km per day, with a record of 135 km on the Atlantic coast (in 6 hours of driving). In addition, being able to arrive at the campsite without being physically damaged allows you to better enjoy free time with the children. Thus, they keep a good memory of this trip and regularly ask me to plan the next trip on a solar bike.

“Functions” additional ones were discovered as the journey progressed:

Figure 24 In parasol mode for the lunch break, allowing the use of picnic tables abandoned because of the sun

Points for improvement

The concept as it currently stands is fine with us. The points for improvement would be as follows:

- the main tube attachment points under the panels, currently with plumbing fixtures and proper fixing of the longitudinal reinforcements.

- holding the panels without cords would be more aesthetic. Reusing the orientation motors would be technically cleaner, possibly with a servo-control adapted to this twin-carrier / high-panel configuration.

- the hidden power wiring at the level of the steering tube will have to be fixed properly because currently quite chaotic (even if the Anderson distributor allows to have a clean base).

My next bike / or the next evolutions

As the children have grown up in the meantime, they will need to ride their own bikes on our next trips, so electric bikes for children, a 20” and a 24” as light as possible, can – also be with a solar structure adapted to the roof? Everything will depend on the type of panels I could get. A few ideas in mind, but a realization by summer 2023 currently seems too ambitious to me.

Freiburg, 27-12-2022

Contact me: bidon79115@gmail.com